Product Center

View all products >

Product Knowledge

View full product knowledge >

Order Process

Ask more about placing an order >

Send your design or just inspiration

Receive our electronic design artwork for your product (request unlimited revisions if you need)

Agree to the design and receive our physical sample

Agree to the sample and we start production

Your order starts being shipped

Each order from you includes the following services

7/24 hours of service

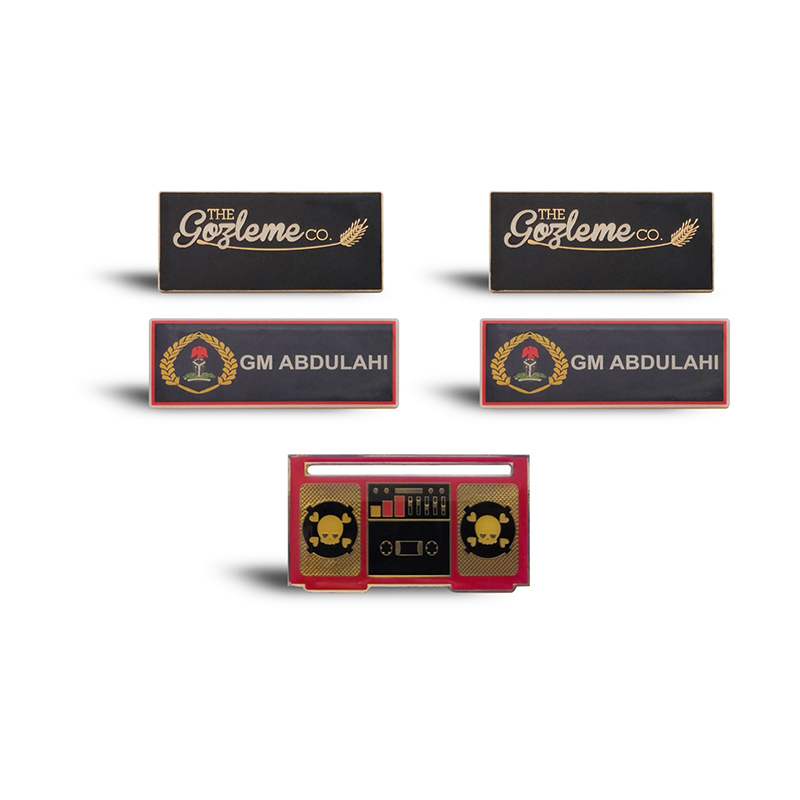

Direct to GM office at your request

Free draft design and unlimited revisions

Diverse payment systems

The fastest production

Order progress inquiry at any time

Diverse express options

Discount as a regular customer

About Our Company Profile

Diverse Premiums

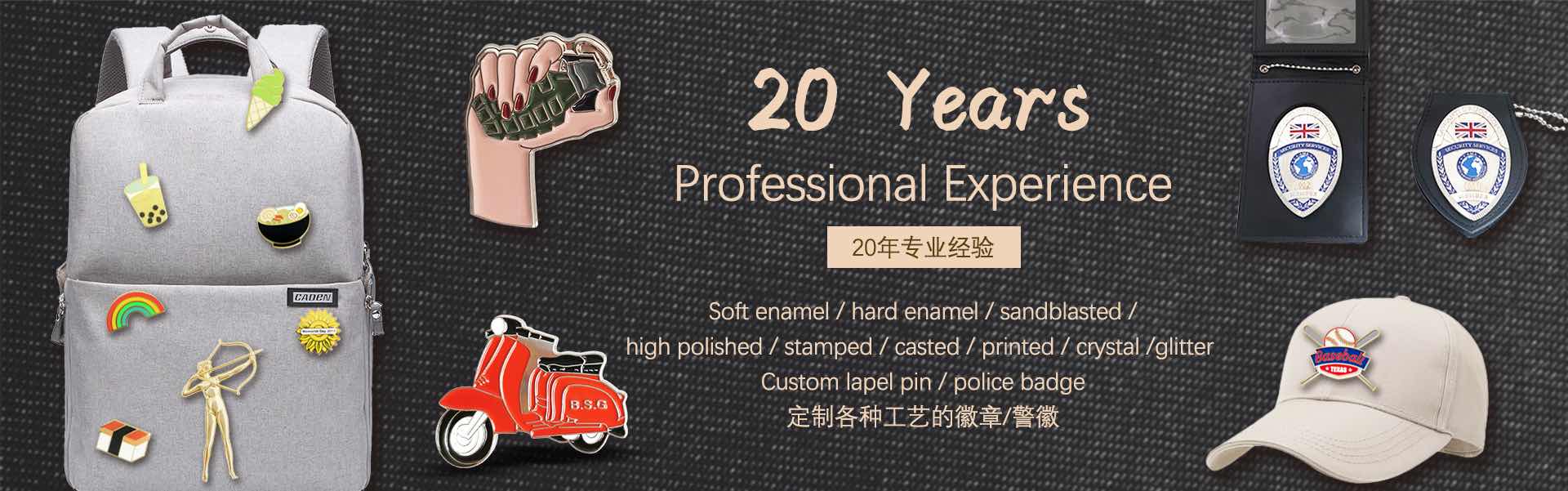

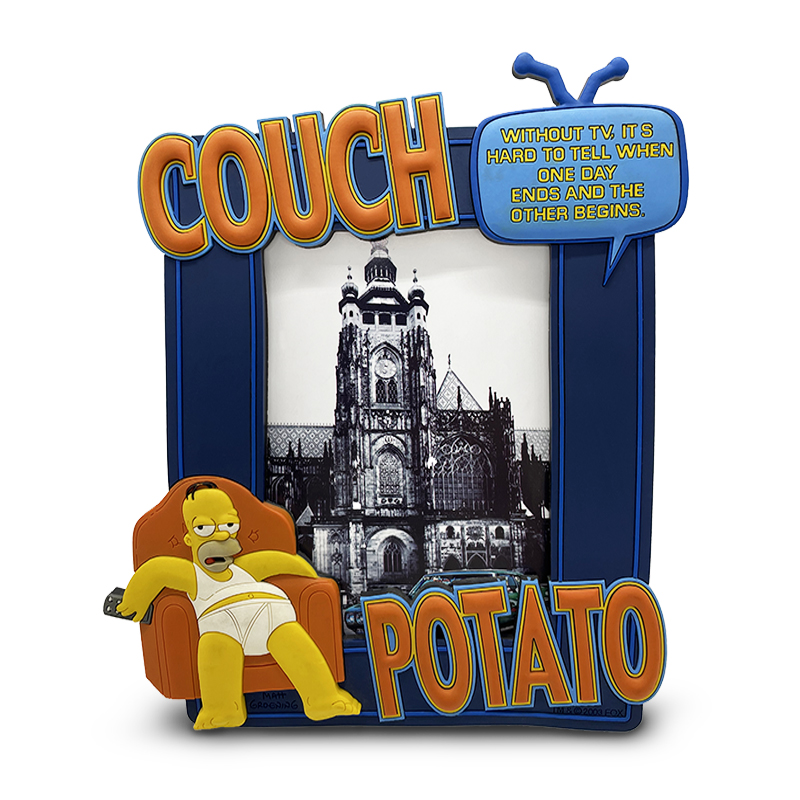

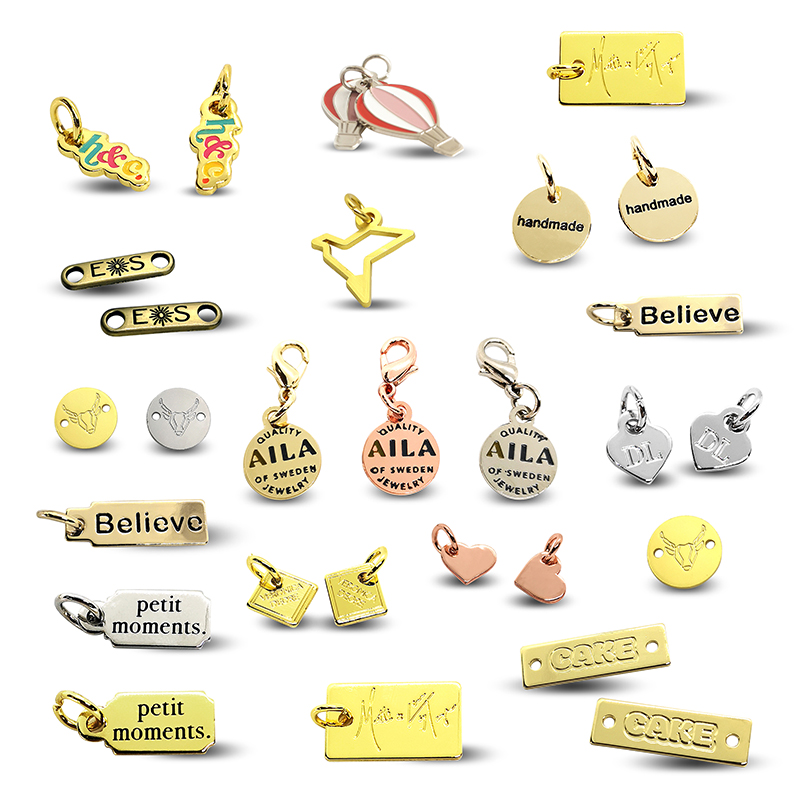

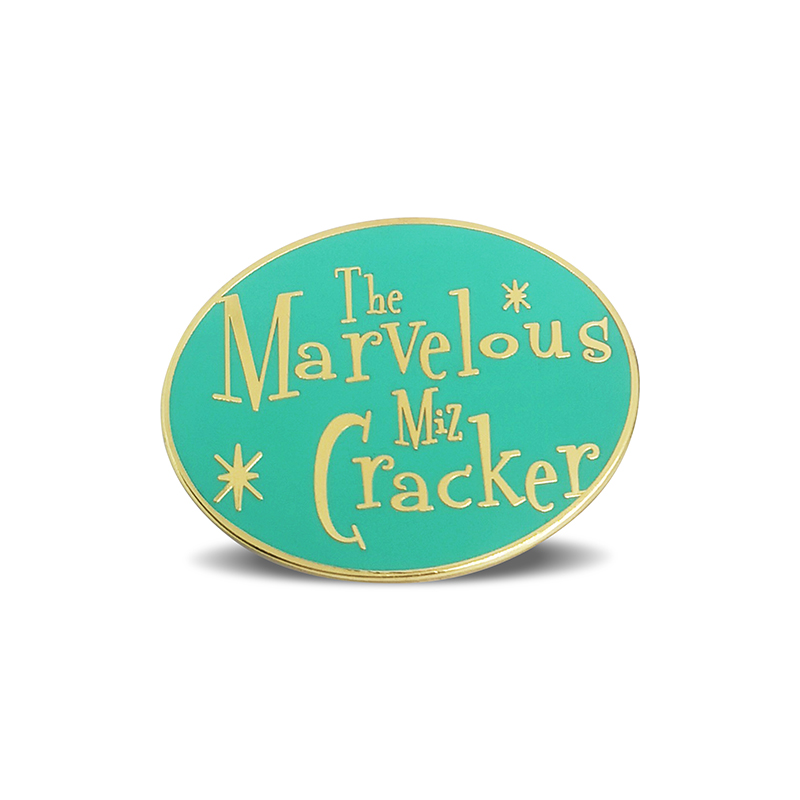

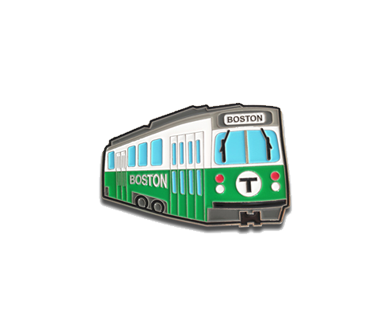

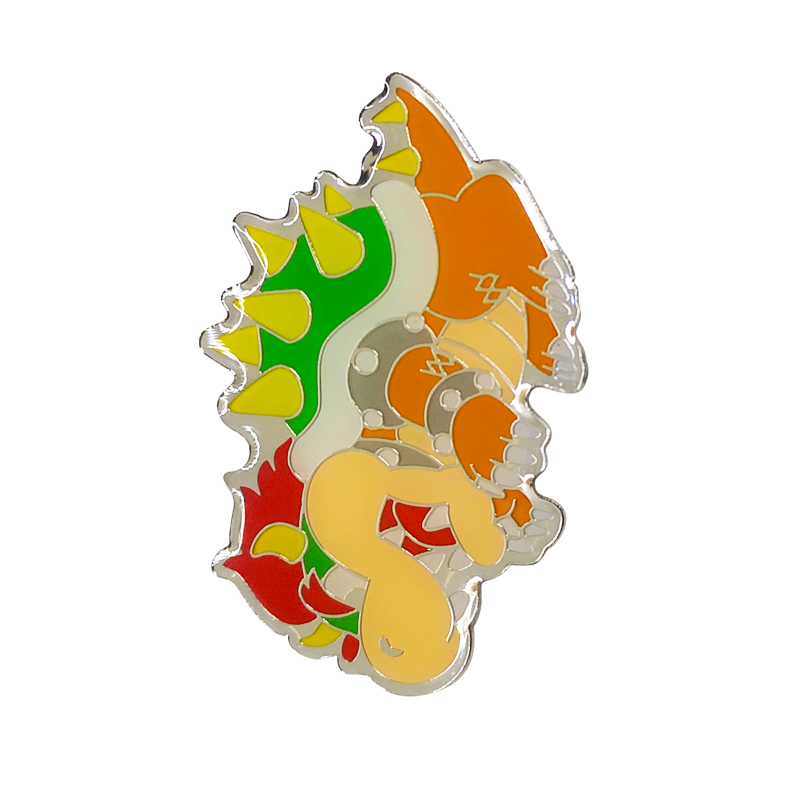

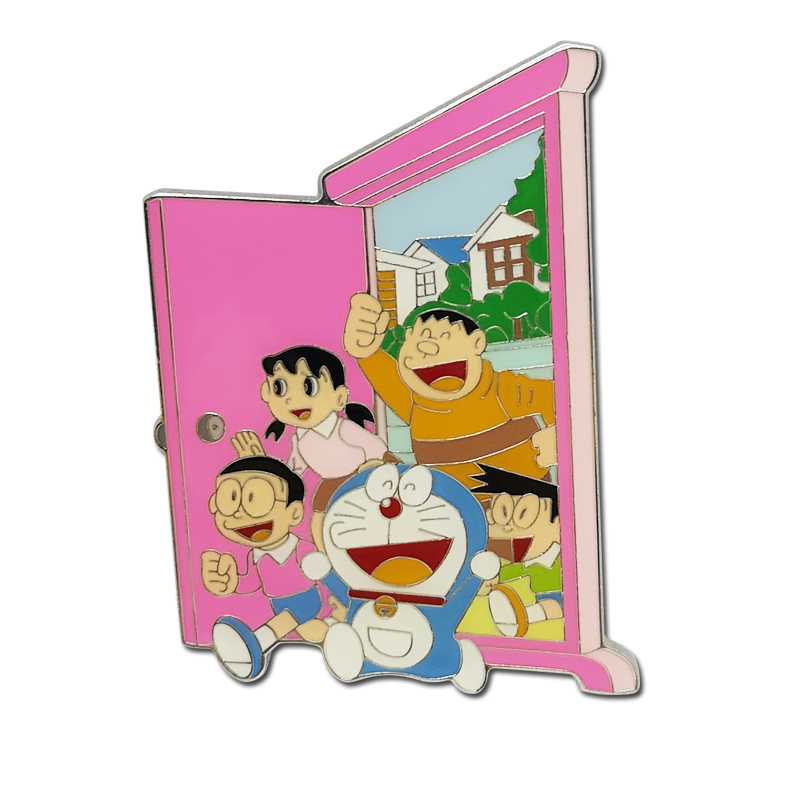

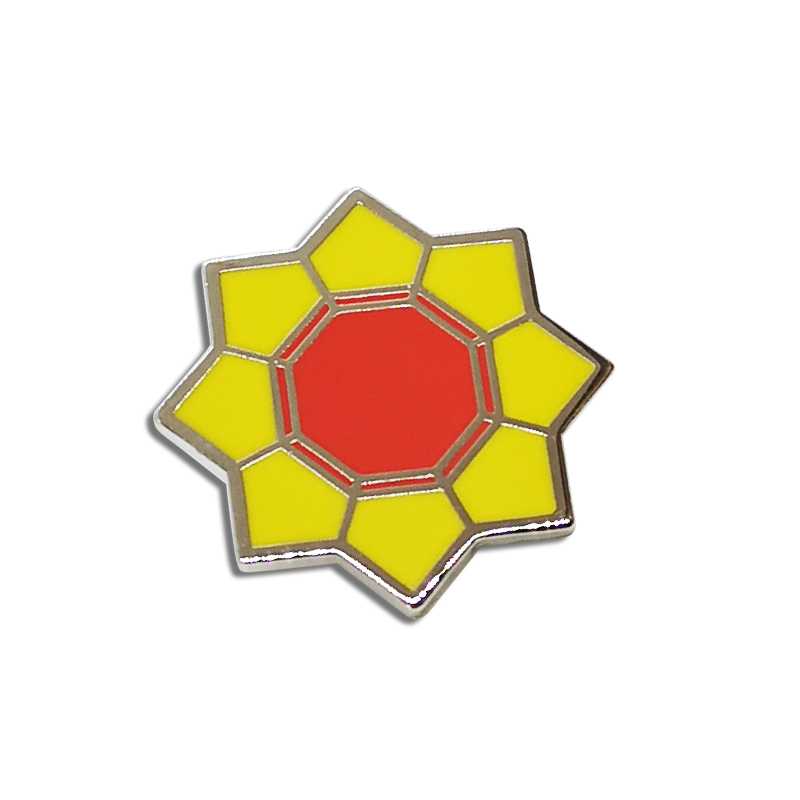

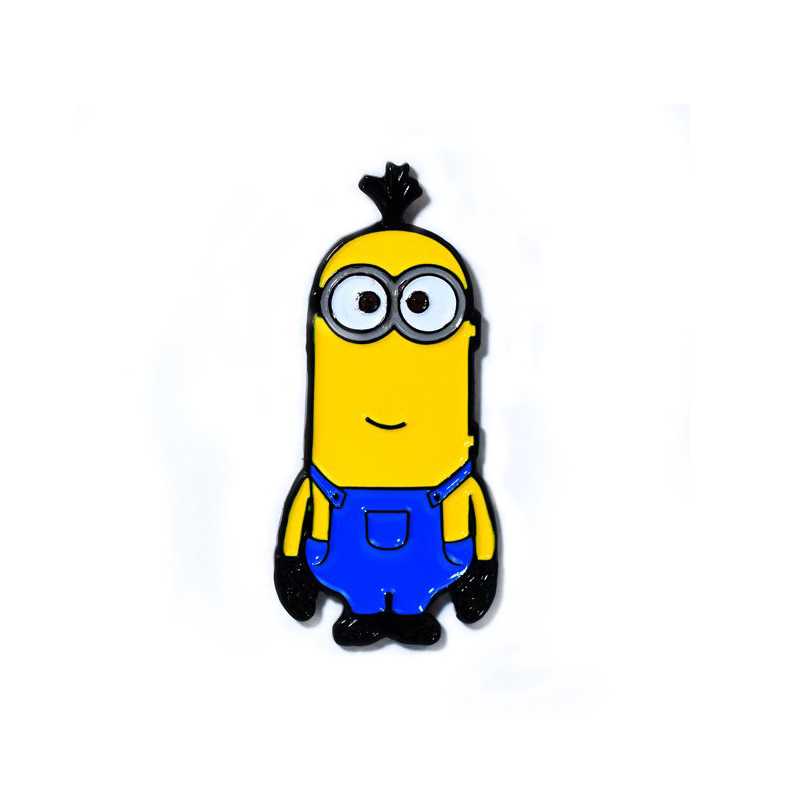

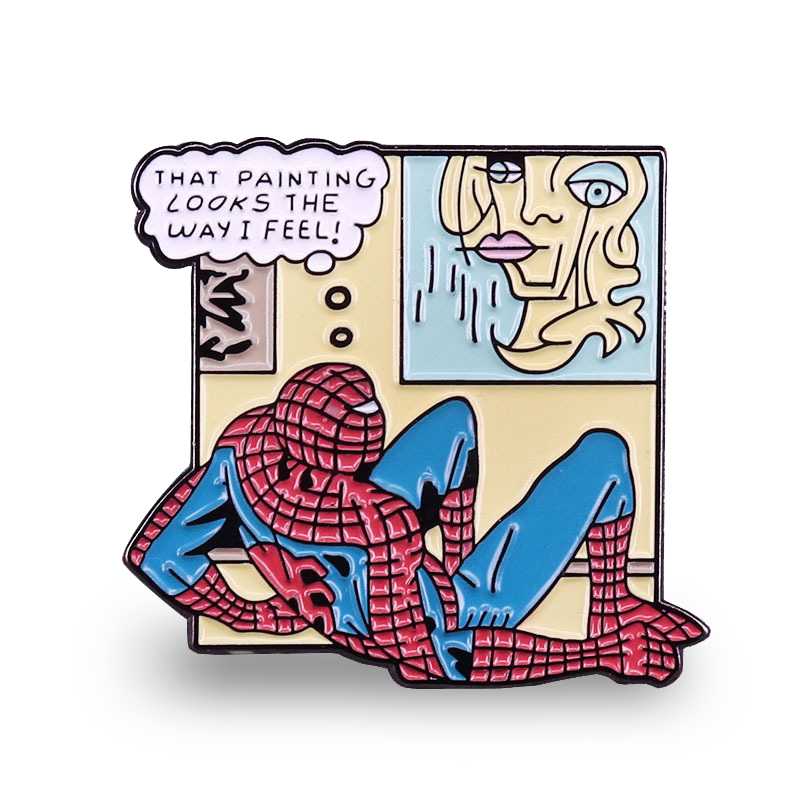

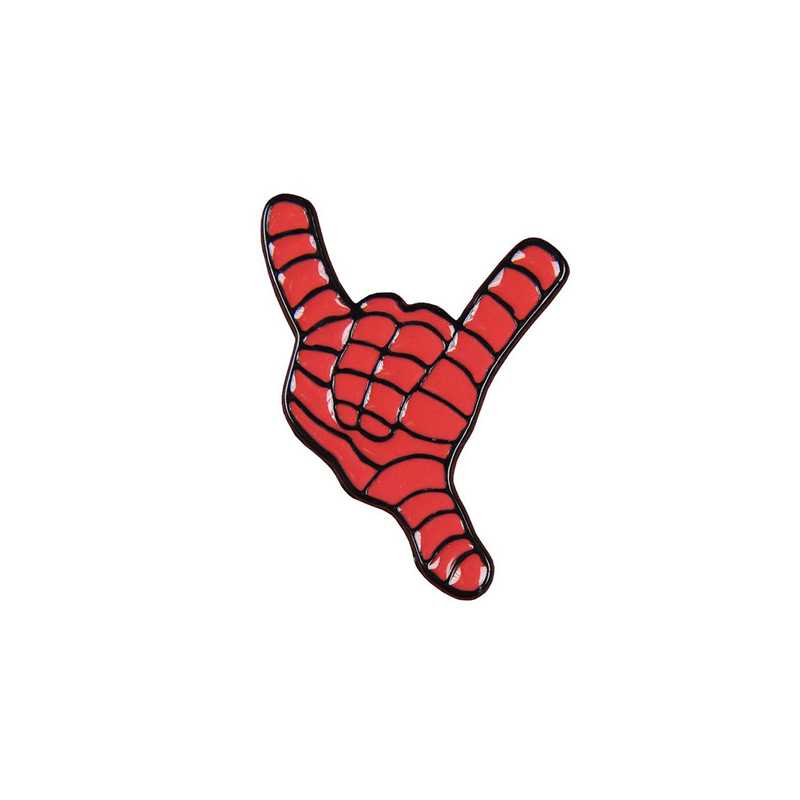

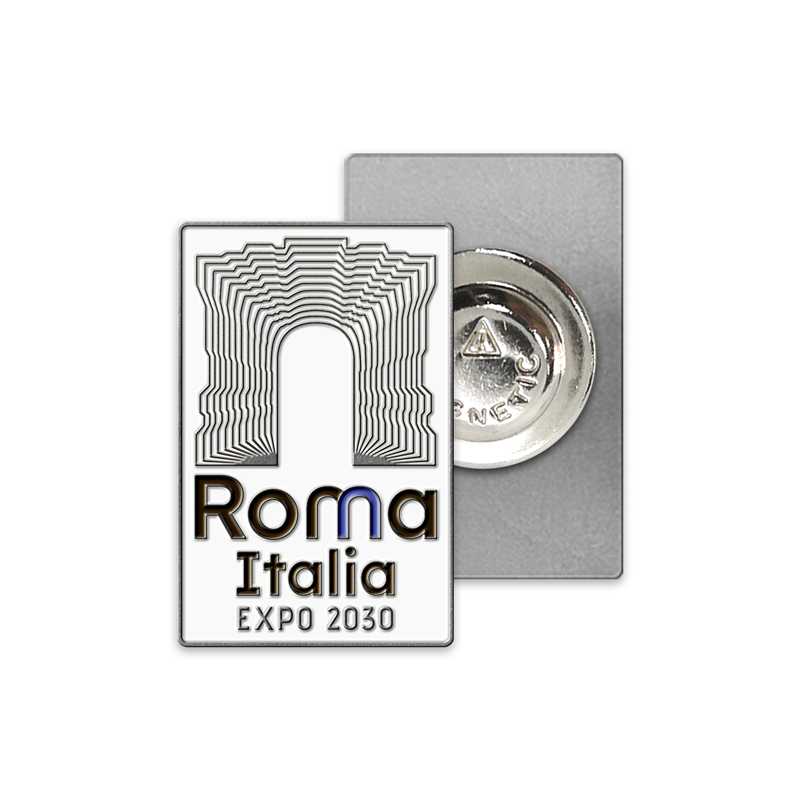

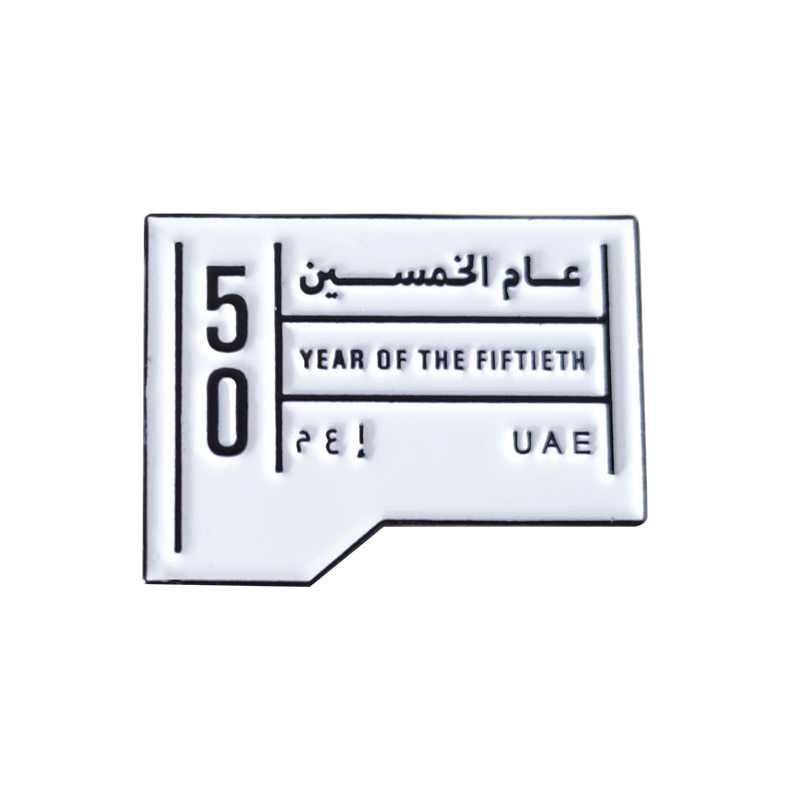

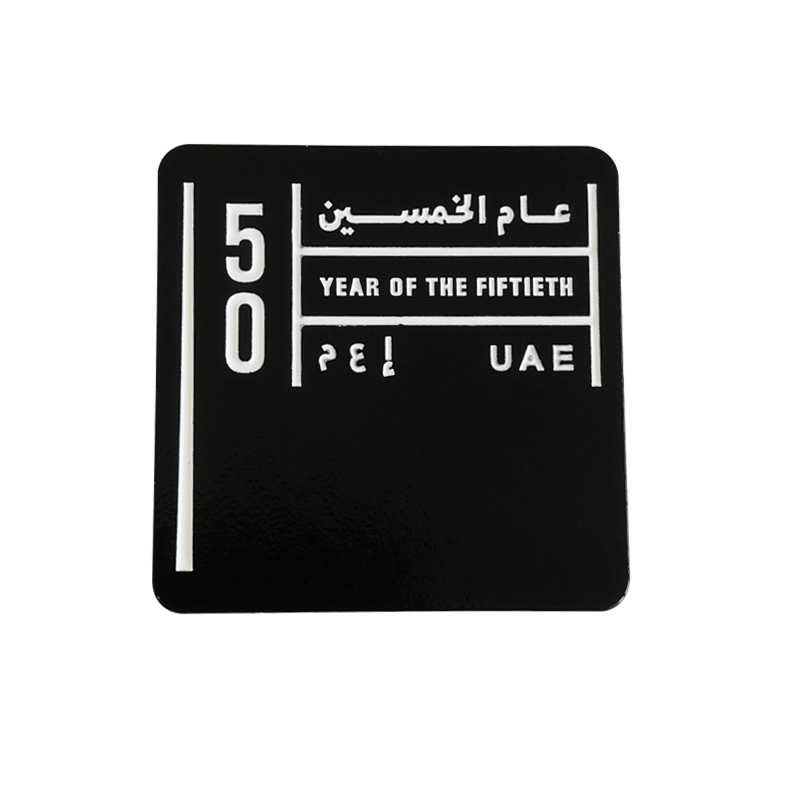

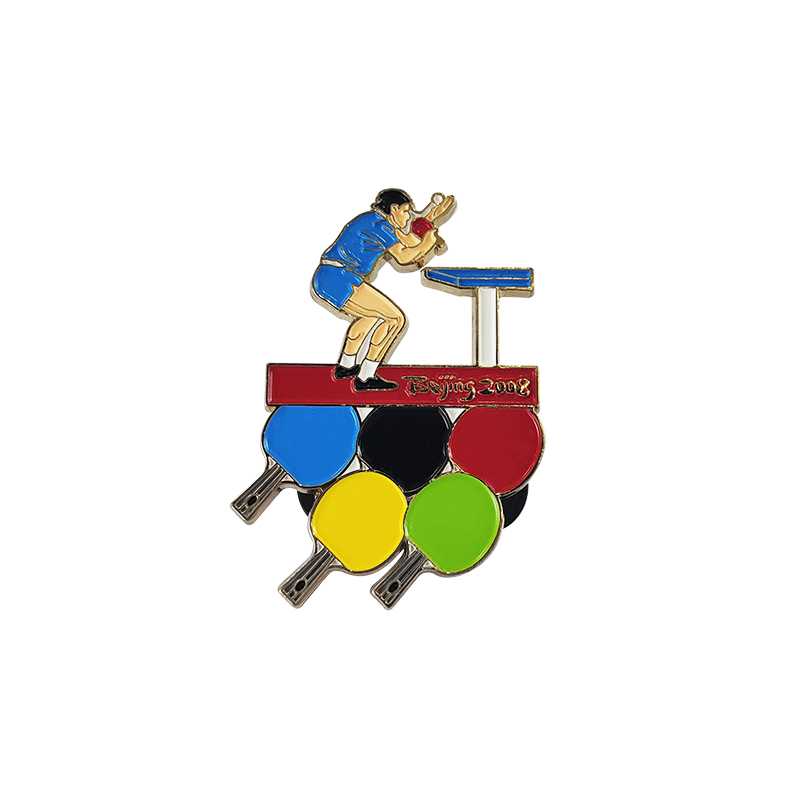

We specialize in the production of a variety of customized crafts, including badges, nameplates, medals, commemorative coins, keychains, bottle openers, cufflinks, tie clips, luggage tags, necklaces, picture frames, etc. Guided by demand, we design and produce custom gifts, corporate logos, and souvenirs that combine quality and taste, meeting your precise needs in various occasions. We are not just manufacturing, but also creating unique value and image for you.

Superb Quality

Since its establishment in 2004, ASNY has always adhered to the principle of "customer-centric, stable and reliable", committed to providing customers with excellent craft production services. We firmly believe that through stable production capacity and flexible business level, we can support customers to achieve long-term agile innovation goals. After years of efforts, ASNY has become a leader in the field of craft manufacturing.

Leading Technology

ASNY is driven by technological innovation, with advanced production equipment and multiple mature production lines. From cloisonne, imitation enamel, paint to stamping, injection, printing, our technology covers all aspects. In terms of coloring, we can meet customers' needs in enameling, imitation enameling, and painting. We have our own electroplating production line and stable accessory and packaging suppliers.

Stable & Reliable

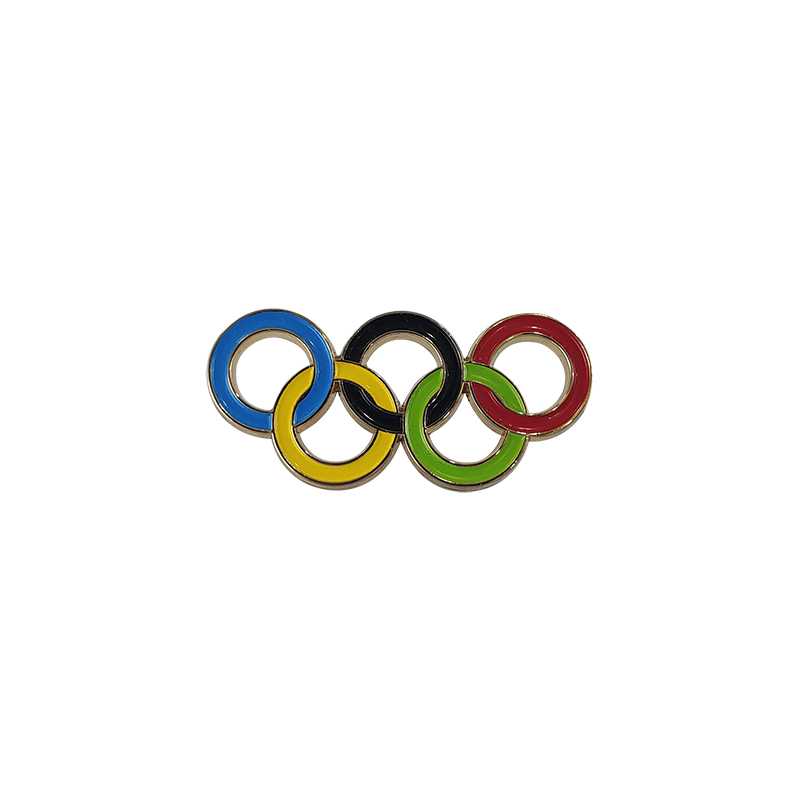

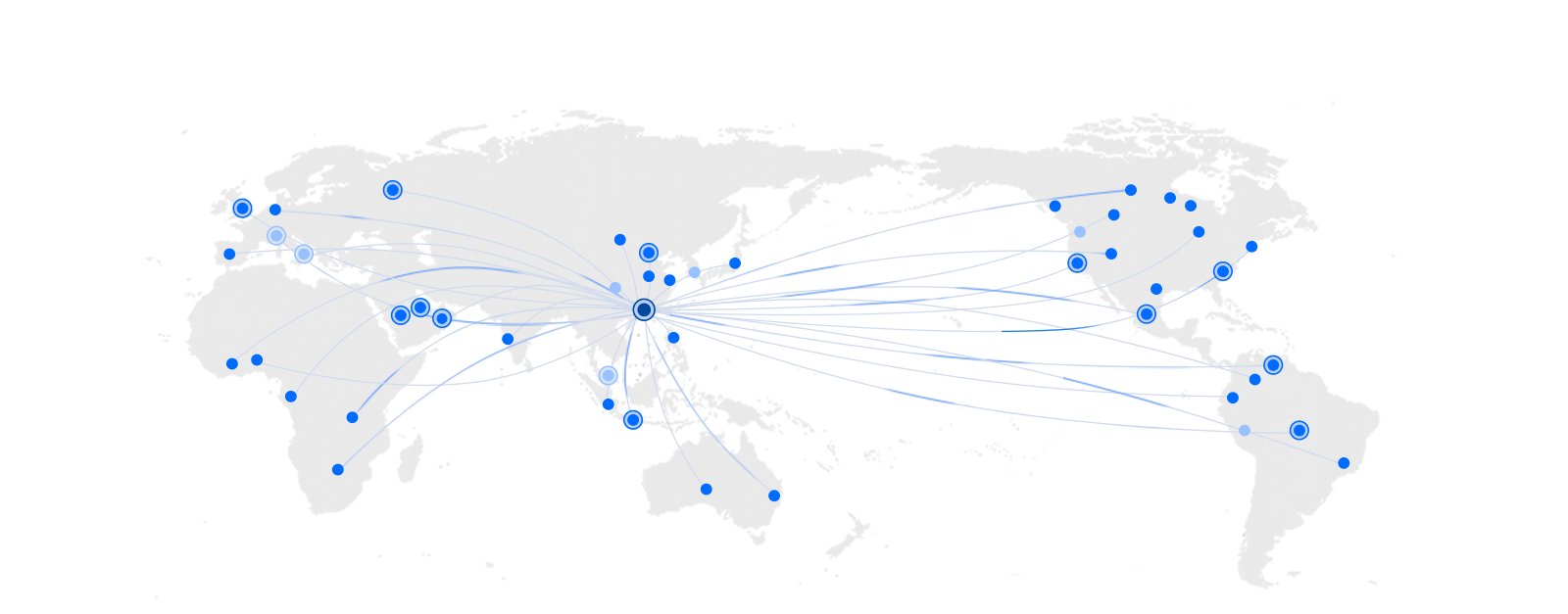

ASNY focuses on quality, and through strict quality control, we ensure that each product reaches a high standard. With 20 years of manufacturing experience and long-term cooperative relationships with customers in more than 40 countries, we have become an authorized manufacturer for 7 of the Fortune 500 companies. We have participated in the production of series products for the 2004 Athens Olympics and various World Expos. You can trust our stability and reliability.

Data Source: Business Live Statistics Data; Alibaba Online-Shop Sales Data

ASNY CEO – Mr. Bailiang Wang

With Bailiang Wang as the chairman of the board, ASNY has a professional high-level design team that can meet customers' specific and even complex requirements. On the business side, we are committed to efficiently meeting customers' needs for certificates, payment methods, shipping methods, and quality control.

Look for more information about our team >

Trust and Choice from Many World-class Brands around the World

Our Export Data

20

Years of export experience

7

Times as a world‘s top 500

authorized manufacturer

50

Productions for global

events

40

Export Value in Million USD

News and Blog

Click for more news and blog >

A Full Range of Worry-free Exclusive Services

Online Consultant

Online Consultant

Using online communication for questions, and you will get the quick answers.

Communicate now

Feedback

Feedback

Feedback any suggestions you have for ASNY here, and ASNY will be better in the future.

Submit feedback